[Avg. Read Time < 4 mins]

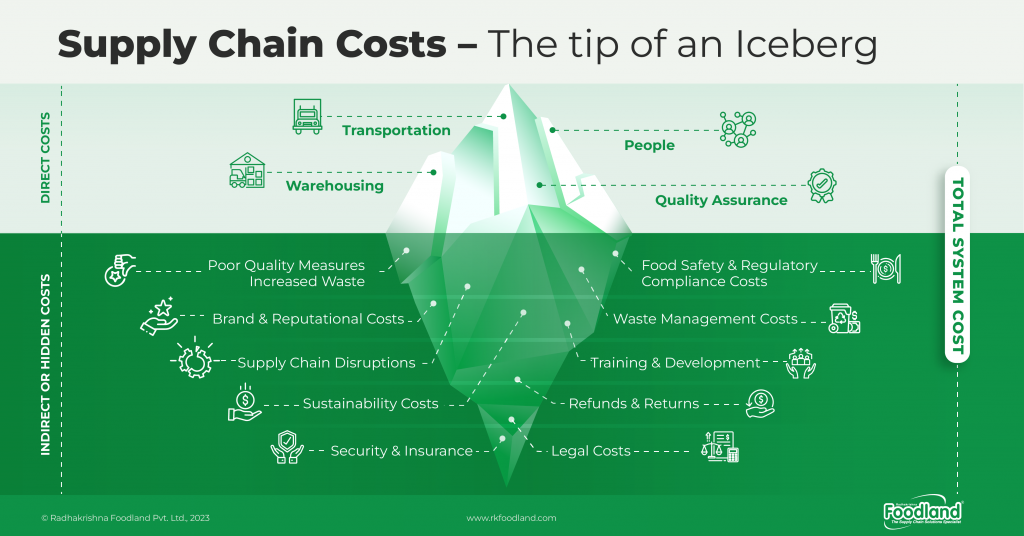

Unlocking the full potential of a business’s limited resources to drive profitability is like uncovering a hidden treasure! The ability to meticulously manage every rupee and gain the most out of it is an art mastered by a handful of businesses in the food industry. It requires a cohesive approach towards expenditure while ensuring the available resources are used optimally. Historically, businesses have focused their strategies on cutting costs, which has proven successful. However, in today’s fast-paced competitive markets, there is no longer a one-size-fits-all approach. In addition to profitability, companies today need to focus on revenue growth, customer satisfaction, market share, employee satisfaction, sustainability, and other factors equally. Traditional supply chains focused on optimizing individual components, such as sourcing, warehousing, and transportation, without considering how they would interact with other parts of the system. This individualistic approach was then applied to cost management strategies often resulting in cost cutting. However, with changes in technology, sustainability focus and rising consumer expectations, companies that take a strategic and forward-thinking approach to food supply management can optimize the entire system costs, from sourcing to delivery, and are most likely to succeed in today’s fast-paced markets.

Let us explore the importance for food businesses to shift their focus from short-term operating costs to outcome-driven total system cost.

Why Looking at Operating Costs Alone is No Longer Enough?

Looking at operating costs alone is a short-sighted approach that fails to consider the bigger picture of business performance. In today’s fast-paced world, changes in technology, customer expectations, and supply chain dynamics are driving the need for a more comprehensive view of costs. A narrow focus on reducing costs can lead to short-term gains but can ultimately compromise the long-term success of the business.

For example, a company that cuts costs by using low-quality materials may save money in the short term but may experience higher maintenance and repair costs, lower customer satisfaction, and damage to its reputation in the long run.

Similarly, while a transport vendor offering the lowest quote may appear to be a cost-effective option, however there is a risk that they may compromise on availability, leading to unforeseen delays and availability issues for the customer.

Companies should focus on long-term sustainable growth by taking a holistic approach to managing their operations. This includes considering factors such as maintenance, upgrades, downtime, quality issues, loss of sales, and reliability in addition to traditional measures such as cost and efficiency. By doing so businesses can gain a competitive edge and create more value for their stakeholders. For example, investing in preventive maintenance and regular upgrades can help ensure the consistent functioning of machinery and equipment over time – reducing costly breakdowns while also improving reliability. Additionally, investing in technologies that enable businesses to track customer behavior or improve product quality can lead to increased customer loyalty and higher sales volumes. All these investments contribute towards long-term sustainable growth.

The Indirect Impact of Ignoring Total System Cost

When organizations primarily focus on reducing operating costs, they may overlook the interdependencies of various factors that impact the overall performance and value of a business. This can result in suboptimal decision-making that compromises the quality, safety, or sustainability of the product or service.

For example: Incorporating advanced data analytics into the existing supply chain system could enable businesses to better monitor production processes and optimize inventory levels. By introducing automation into their system, companies can boost efficiency and productivity, while also optimizing people costs improving productivity.

A company that invests in sustainable practices and materials may have higher upfront costs but may benefit from increased efficiency, reduced waste, enhanced brand reputation, and improved customer loyalty.

Thus, by adopting a total system cost approach, businesses can gain a more comprehensive view of their costs and opportunities for improvement, leading to more informed decision-making and better outcomes.

Implementing Total System Cost: A Game-Changer for Business Continuity

Total System Cost (TSC) approach has the potential to revolutionize cost management and support business continuity by providing a comprehensive view of the total cost of a product or service. However, successfully implementing the TSC approach requires certain pre-requisites. These include having a clear understanding of the business costs, access to accurate data, top management support, cross-functional collaboration, and a culture of continuous improvement. Without these pre-requisites, it may be challenging to implement the TSC approach effectively and achieve the desired outcomes. To achieve successful implementation of TSC, businesses also need to have a level of system integration that allows visibility across the value chain. Additionally, a comprehensive cost analysis is essential to identify all cost drivers and prioritize cost optimization efforts based on their potential impact and alignment with strategic objectives. By defining clear roles and KPIs that are aligned with business objectives and not merely based on cost reduction, businesses can achieve a more sustainable cost management approach that supports business continuity and growth.

In conclusion, businesses must embrace a growth mindset and move away from the traditional cost-cutting approach to stay competitive and future-ready. The Total System Cost (TSC) approach is a powerful tool that can help businesses achieve this by providing a comprehensive view of costs and their implication. However, it is important to note that not all businesses may be ready to transition to the TSC approach, and it may require a certain degree of readiness and maturity. Nevertheless, businesses can start developing the capabilities and work towards optimizing costs while aligning resource KPIs with their overall business objectives. As supply chain leaders, it is essential to recognize the importance of this shift in mindset and take proactive steps towards building a culture of cost optimization and continuous improvement.

Related Content | Foodland’s Resources

Quality Cost Reduction – Impact of quality-related costs and how to reduce them sustainably

Collaborative relationships built on value — not cost

The Big List of Supply Chain KPI Mistakes to Avoid