[Avg. Read Time < 6 mins]

In today’s fast-paced and highly competitive world of the food industry, achieving supply chain resilience is essential for businesses to flourish and maintain a leading edge. As consumer demands continue to drive the industry forward, the ability to effectively navigate challenges and capitalize on opportunities becomes paramount. It’s no wonder that more than 90% of food businesses rely on strategic supply chain partnerships to manage dynamic demand and ensure smooth operations. However, as the number of collaborations grow, not all endure; a significant proportion falter in short period. Consequently, the crux of long-term success lies not just in forging partnerships, but in selecting the right partner. Today, we delve into the 3C Model – Capability, Capacity, and Competence – a comprehensive approach to evaluate potential partners, underpinning the development of strategic, resilient, and enduring partnerships in the food supply chain industry. This blog seeks to empower Food Business CXOs by providing them with the knowledge they need to assess and evaluate potential supply chain partners before making a final selection.

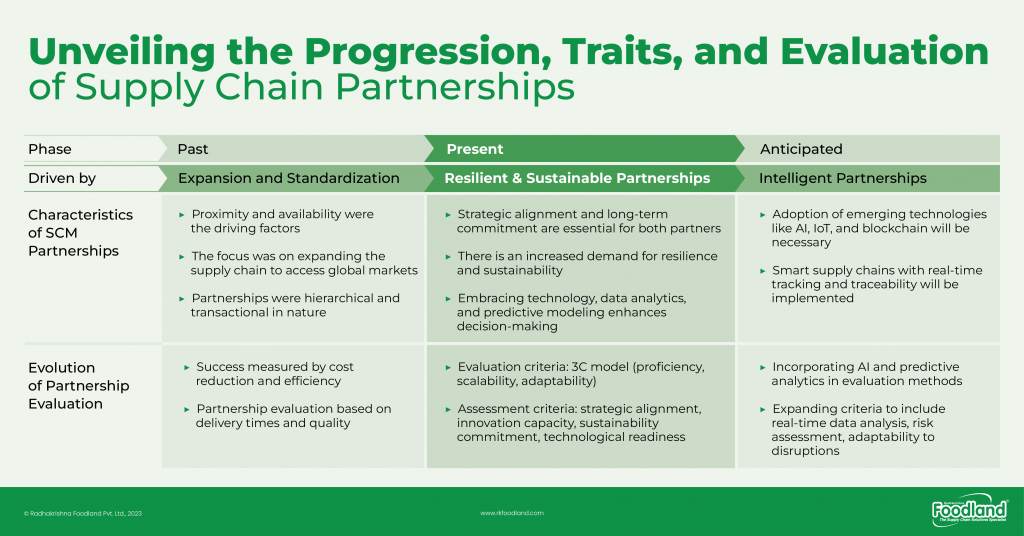

The Evolution of Partnerships in Food Supply Chain

The history of partnerships in food supply chain is a fascinating tale of evolution and shifts in paradigms. If we go back in time, we’ll see that the roots of these partnerships were often basic, forged by necessity rather than strategy. They were dictated by simple principles of proximity and availability, rather than a well-evaluated match of capability or competence. Yet, as the industry grew in complexity and global reach, so too did the sophistication of these partnerships. Traditional methods of partner evaluation emerged, scrutinizing aspects such as price, delivery speed, and reliability. But these metrics, though important, had their limitations. They could not fully account for the intricate, interwoven factors that drive success in the food supply chain, nor could they predict the resilience of a partnership under the unpredictable challenges thrown by a dynamic global market. It was apparent that a more comprehensive approach was needed, one that could holistically appraise potential partners and anticipate the fluctuations of the industry. That’s where our journey brings us to the present, and to the dawn of the 3C Model – Capability, Capacity, and Competence. This model is the culmination of RK Foodland’s 35 years of experience in fostering partnerships, tailored specifically for contemporary food businesses. It serves as a compass to navigate the intricacies of the supply chain and lay the foundation for long-lasting, prosperous partnerships.

Diving Deep into the 3C Model: Capability, Capacity, and Competence

Building upon our exploration of the evolution of partnerships in the food supply chain industry, we now delve into the 3C Model – Capability, Capacity, and Competence – the trinity that redefines the parameters of effective partner evaluation.

The first pillar, Capability, reflects a partner’s technical prowess, functional capabilities, and domain expertise. Think of it as the ‘stamina’ of a potential partner, the foundational strength that allows them to fulfil their role. For instance, a partner’s understanding of food safety regulations, mastery over quality control processes, and specialized skills in handling, storing and distributing food are all components of capability. Furthermore, a partner’s resource management strategy, encompassing human resources, finances, and physical assets, significantly impacts their capability. Effective resource management ensures operational smoothness, creating a stable, reliable supply chain that can weather the inevitable ups and downs of the food industry.

Next is Capacity, often viewed as the ‘muscle’ of a partner. In the context of the food supply chain, this implies the ability to handle volume requirements efficiently, adapting to the demand fluctuations due to seasonality or market trends. For instance, a logistics partner with a robust capacity to handle temperature-controlled transportation and extensive warehousing facilities can effectively manage the intricate requirements of perishable goods, ensuring their safe and timely delivery throughout the supply chain. Complementing this is the infrastructure, such as warehouses, transport facilities and distribution networks, which allow for the efficient and timely delivery of food products, ensuring that the freshest produce reaches consumers. Advanced technologies in warehouses, like robotics and data analytics, can increase capacity by 20% and cut processing time by half. Assessing partner’s capacities enables businesses to harness these advancements, driving efficiency and competitiveness in the supply chain.

Finally, we come to Competence, the ‘brains’ of the operation. It is a partner’s knowledge of the industry, their expertise, and more importantly, their ability to handle change. With technology driving competitive advantage, and emerging trends like intelligent edge ecosystems and robotics investment gaining prominence, businesses must assess partners’ competence. By aligning with competent partners, businesses can navigate technological advancements. From understanding emerging consumer trends, like the plant-based movement, to staying updated with regulatory changes and technological advancements, competence forms the bedrock of an enduring partnership. Coupled with the ability to innovate—be it providing real time insights for businesses to launch new products, embracing sustainable practices, or streamlining processes—competence provides a partnership the competitive edge necessary to not just survive, but thrive in the rapidly evolving food supply chain landscape.

Together, these three components—Capability, Capacity, and Competence—form a comprehensive evaluation model that allows Food Business CXOs to identify, cultivate, and sustain successful partnerships, setting the stage for enduring growth in the demanding food supply chain industry. You can download the checklist to evaluate based on the 3C Model here.

Impact of the 3C Model on Long-term Growth and Continuity

The 3C Model revolutionizes partnerships in the food supply chain industry, fostering long-term growth and continuity. By applying the 3C Model, partners unlock a multitude of benefits that extend beyond short-term gains. Enhanced collaboration and synergy drive innovation and creativity, while improved problem-solving and decision-making capabilities result from aligning strengths and expertise. Trust and open communication enable strategic investments, shared risks, and rewards. The 3C Model also boosts efficiency, collaboration, and sustainability by streamlining processes, optimizing resource utilization, and integrating responsible practices. Strategic partnerships, evaluated through the 3C lens, facilitate market expansion, knowledge sharing, and risk mitigation. They enhance supply chain efficiency and strengthen market competitiveness. Ultimately, the 3C Model empowers partners to navigate challenges, seize opportunities, and shape a sustainable future for the food supply chain industry.

To sum up, the supply chain partnerships have become the backbone of success and sustainability and the 3C Model – Capability, Capacity, and Competence – serves as a transformative framework for evaluating and forming strategic alliances. By embracing this model, businesses unlock a host of long-term benefits. Enhanced collaboration and synergy foster innovation and drive creativity, while improved problem-solving and decision-making capabilities lead to more effective strategies. The model’s emphasis on sustainability ensures responsible practices that align with evolving consumer expectations. These strategic alliances, evaluated through the 3C lens, play a vital role in fostering long-term growth and continuity. They enable access to new markets, promote knowledge sharing, and drive supply chain effectiveness. By mitigating risks and fostering innovation, partnerships fuel market competitiveness and resilience. As the food supply chain industry continues to evolve, the 3C Model empowers businesses to adapt, thrive, and shape a sustainable future.

Embrace the power of the 3C Model today and forge meaningful partnerships that pave the way for enduring success in the dynamic world of food supply chains.

Related Content | Foodland’s Resources

Creating a competitive supply chain advantage through connected communities

4 Reasons Why Supply Chain Collaboration Is Critically Important

5 Best Practices For Successful Supply Chain Partnerships