Orchestrate demand and supply planning for better predictability

Leverage consumption insights for increased profitability

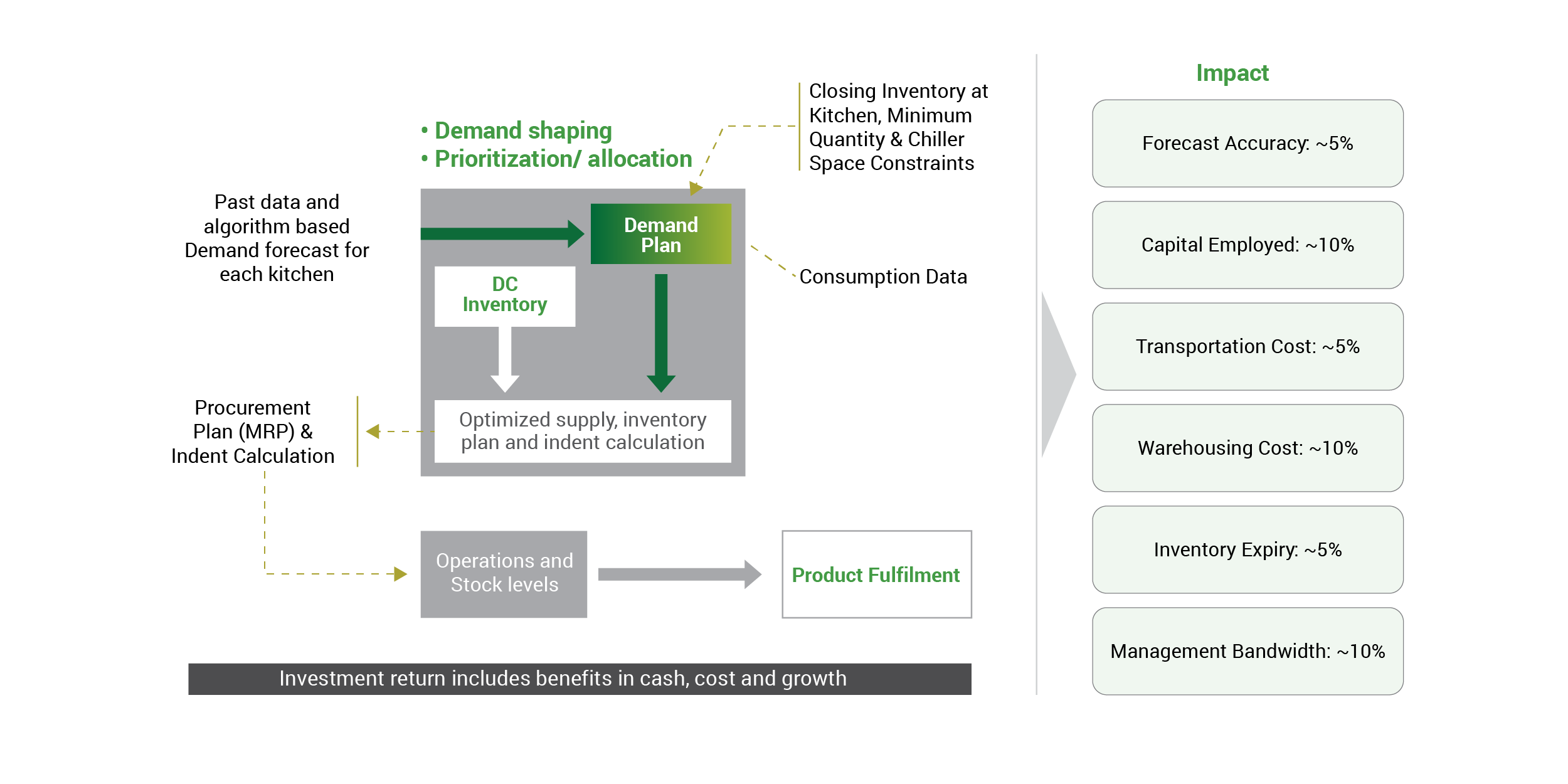

Supply chain planning in consumption-driven categories can be complex. The ability to accurately sense demand on time becomes a critical driver for revenue growth for food brands. We have coded our comprehensive knowledge of the industry into a proprietary methodology to forecast and fulfill demand while assisting businesses in capitalizing on every revenue opportunity to grow profitably. Accurate demand projections improve supply planner visibility and transparency. Supply chains work smoothly when demand planning coordinates with all business processes, positively impacting business revenues.

Understand why focusing on consumer trends is the need for modern supply chains

Outcome driven demand planning for precise predictability

Demand planning greatly affects supply planning systems by projecting future demand trends, allowing planners to better adapt to changing consumer needs. DemandXPro is our intelligent proprietary tool for forecasting demand accurately across channels and product categories, particularly in the context of the Indian food service industry. The system uses machine learning algorithms to forecast future demand and give actionable insights based on transactional and semi-structured micro and macro data such as seasonality, festivals, promotions, growth trends, and changing culinary preferences. Combinations of Statistical and Machine Learning Methods specific to India’s food consumption patterns are deployed to arrive at the best possible solution for the most complex problems in the supply chain. These help with:

- Increased forecast accuracy

- Reduced loss of sale

- Near-zero expiries

- Consolidated actionable insights

Know how we enabled our QSR client in achieving accurate and reliable demand forecasting

Demand Planning

Send download link to:

Improve supplier performance through effective planning solution

Measuring, analyzing, managing, optimizing, and tracking supplier performance is critical to achieving predicted savings. Our Supplier Management System is an integrated solution that enables detecting, tracking, and assessing supplier lifecycle risk, correcting systemic risks, and managing supplier interactions. This is achieved through streamlining logistics procedures to increase efficiency and reduce delivery costs. The system also enables Material Requirement Planning to ensure that suppliers receive the correct purchase orders on time along with visibility on demand forecasts and safety stocks thus reducing stockouts and payment delays. Supplier scorecards record quantitative and qualitative performance data giving you better control over supplier data.

Outsource your procurement to unlock greater efficiencies in your P2P cycle

Regulate cash flow through effective inventory planning

Our inventory planning methodology promotes a smooth supply chain by allowing businesses to keep a close track of their inventory thus avoiding overstocking or outages by knowing what they have in stock, where it is, and when it needs to be refilled. With our decades of experience in the food ecosystem and understanding of inventory patterns, we help firms better adapt to food industry fluctuations and anticipate changing trends. Our integration of demand and supply indicators can help develop effective inventory planning. Monitoring inventory movement provides a greater awareness of market circumstances, hazards, and delays, allowing for more flexible planning. Good inventory management prevents other overstocking issues like product expiries and wastages, helps respond to market changes quickly and reduce costs.

Manage inventories efficiently with our agile warehousing solutions

Planning solutions tailored for success

- End-to-end Demand Planning

- Demand Planning Strategy

- Demand Planning System Design

- Product Life-cycle Design

- Demand Planning Management & Operations

- Advanced Insights and Analytics

- Material Requirement Planning

- Capacity Planning

- Procure to Pay Cycle Management

- Supplier Performance Management

- Integrated Planning

- Inventory Rationalization

Together we can achieve these planning outcomes

Optimised inventories

Improved supply chain visibility

Increased profitability

Improved order fulfilment

Improved production scheduling

Increased cashflow

Connect with our experts to re-imagine your supply chain planning strategy

Resources

FAQs (Frequently Asked Questions)

RK Foodland’s integrated planning services encompass various components to optimize the supply chain operations in the Food Service and Food FMCG sectors, such as:

- Demand Forecasting: Predicting future customer demands to ensure that adequate inventory levels are maintained.

- Supply Planning: Coordinating with suppliers to ensure that the necessary products are available to meet customer demands.

- Inventory Management: Strategically managing stock levels to optimize storage costs and ensure product availability.

Integrated planning enhances supply chain management processes by:

- Forecast Accuracy: Enhanced forecasting utilizes historical and market data, enabling precise demand predictions and strategic decision-making.

- Inventory Management: Improved forecasting optimizes inventory levels, freeing up capital and controlling costs associated with excess inventory, thus enhancing cash flow.

- Improved Supplier Performance: Clear demand visibility enhances supplier coordination, ensuring timely and accurate deliveries, improving overall supplier performance.

- Product Availability and No Loss of Sale: Consistent product availability, preventing stockouts and lost sales, thereby boosting customer satisfaction and business profitability.

RK Foodland manages peak demand periods by:

- Integrated Planning: Collaborating with QSRs to plan for promotions or festive seasons well in advance, ensuring that supply chains are prepared to handle increased demands.

- Inventory Management: Adjusting inventory levels based on anticipated demand spikes during promotions or festive seasons.

- Enhanced Coordination: Improving coordination with suppliers and other supply chain partners to ensure smooth operations during peak periods.

- Real-time Monitoring: Continuously monitoring supply chain operations to identify and address any issues promptly, ensuring that customer demands are met efficiently.