The food ecosystem is changing and what was once supply-driven and linear, is now under becoming demand-driven and transformative. Changing consumer habits, trends, convenience and demographics, now drives demand, access and delivery. These preferences have been accelerated by the pandemic and to adapt to these emerging changes, supply chains need to anticipate, evolve and respond quicker. This makes supply chain partnerships quintessential to re-imagine, re-define and re-configure the entire value chain. Forming equitable relationships and exchanging value among the ecosystem participants is a key enabler of customer experience and business growth. If you are unfamiliar with why supply chain partnerships are essential in the food ecosystem today, understand it better here.

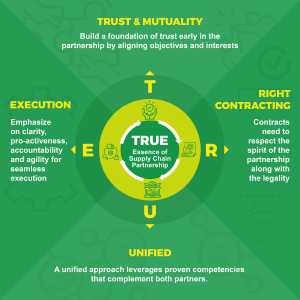

For building a successful partnership that assures sustainable business outcomes, getting the ingredients right is crucial. Based on our experience and expertise, we have recognized 4 key pillars that form the building blocks for co-creating partnerships in food ecosystem.

1. Trust & Mutuality

Establishing trust early on allows all parties to openly share knowledge and create a cohesive environment that gives everyone involved a better chance of success. The journey is difficult at first, and both parties must establish credibility and reliability. Creating transparency and consistency enables the partnership to build a long-term, sustainable foundation on which to evolve. This can be strengthened further by aligning objectives and interests, identifying and addressing challenges, resolving issues, and conducting regular reviews.

Building a base of trust and mutuality requires partners to:

- Establish the right context and complexities in-sync with expected outcomes

- Align capacities & capabilities to effectively utilise resources

- Build seamless information flow and knowledge access

- Enable easy course correction to reduce potential mistakes

Trust doesn’t materialize overnight but is a process that occurs over time, and unless a sense of shared purpose and perspective is developed, mutual understanding is difficult to build.

2. Right Contracting & Business Spirit

Supply chain partnerships need more than basic legal agreements to work together. They encompass understanding of complex interrelationships of shared objectives, interests and activities. Before a suitable contract can be crafted, the partners should agree on a shared vision, goals, and process framework. Deciding the performance drivers and setting the right expectations from the start avoids ambiguity and possible conflicts later on. Since creating such a complex agreement has its challenges, contracts need to respect the spirit of the partnership along with the legality.

Some of the key advantages of creating a “win/win” contract include:

- Long-term, equitable relationship

- Re-investing in further development

- Focus on Assurance

- Improved Transparency with no hidden caveats

- Smooth execution and review mechanism

- No miscommunication

- Easy course correction

Several other aspects need to be considered while contract development such as a farsighted view of contracting, structuring a contract that serves as a framework for the partnership, respecting the “spirit” of the business, conflict avoidance and resolution, mutuality, creation and maintenance of order, and alignment of risks and rewards.

An ideal supply chain partnership contract is based on a history of mutual trust and provides a ”governance” structure that allows both parties to operate in a flexible, yet disciplined way, mitigates conflict, and aligns and shares both risks and rewards. Developing mutual experience and trust takes time, and therefore, contracting for partnerships is an evolving process that proceeds in an exploratory way. Learning how to deal, adapt, and relate to each other is a normal part of a productive contractual exercise.

3. Unified & Integrated

A unified approach towards supply chain partnerships unlocks organizational efficiency and leverages proven competencies that complement both partners. Sharing key capabilities like people, process and technology empowers brands to consistently deliver great experience throughout the entire customer journey. The right integration allows end-to-end visibility that helps to access customer data across the entire supply chain. This streamlines business processes and improves predictability allowing the brands to leverage all the information through a single platform. The right people with right talent and required skillset can be utilised across the partnering brands to enhance productivity and efficiency across the value chain.

Some key points that brands need to keep in mind for a smoother integration are:

- Align the long-term vision and short term goals

- Bring in consistency in terminologies

- Ensure all teams are in-sync with the agreed upon plan

- Focus on clear communication

- Think of the big picture

By crafting an integrated ecosystem, data is readily available to all for providing near real-time access to critical information, supporting informed decision making and enabling process execution across the value chain.

4. Execution

Involving the right set of teams from the start who will be involved in execution helps navigate complex partnership. The individuals expected to lead day-to-day operations of the partnership, whether business-unit executives or alliance managers, should be part of the partnership process from the start. This helps navigate complex partnerships at the execution stage better and avoids miscommunications.

Ensuring a smooth execution requires partners to:

- Set up a delivery timeline and project plan

- Outline the governance framework for accountability

- Emphasise on metrics so as to measure what matters

- Agree on a regular review mechanism

Every partnership has its own unique execution challenges depending on the category, geography, previous experience, and strategy. Some markets can present additional challenges involving local cultures, integration norms, and regulatory complexities. An emphasis on clarity, proactive management, accountability, good governance and agility can reduce execution efforts across both partner teams.

Let us be honest: successful supply chain partnerships don’t just happen by chance. Strong partners set a clear foundation for supply chain outcomes expected from the partnership and work towards them. They emphasize accountability within and across partner companies, and they use the right metrics to gauge success, and they are willing to change things up if needed. The true essence of a partnership built on the right balance of the four pillars – Trust, Right Contracting, Unified Approach and Execution and they act as effective prerequisites for initiating discussions in partnerships. Focusing on the agreed-upon priorities can help partnerships thrive and create more value. Supply chain leaders must build partnerships with a constructive attitude, visionary leadership, and a strong commitment to mutual success.

To build a successful supply chain partnership in the food industry requires the right experience and expertise to manage the complexities. Perceiving the drivers and motivators of the supply chain partnership requires some forethought.

To understand these better, connect with our experts >>