Imagine ordering a burger or a cup of coffee and having the power to trace its ingredients back to their sources. This is not a scene from a sci-fi movie; it is the reality of today’s food service industry, revolutionized by smart supply chain technology. In a sector where consumer demands for transparency and quality are skyrocketing, the adoption of technologies offering real-time visibility, traceability, and predictive analytics is no longer optional but essential. Companies that aggressively digitize their supply chains expect to boost annual growth by 3.2% – the largest increase from digitizing any business area. This blog delves into how these technological advancements are not just streamlining operations but are also critical in building customer trust and driving strategic growth in the dynamic world of food service and FMCG.

Recognizing the Imperative for Change

In the ever-evolving landscape of the food service and FMCG sectors, the need for a paradigm shift in operational strategies is more pronounced than ever. This dynamic industry, characterized by its relentless pace and consumer-driven demands, calls for an enhanced operational efficiency and a customer-centric approach to stay competitive. The growing consumer awareness and concern about health and sustainability are reshaping the market as 73% of global consumers are willing to change their consumption habits to reduce their impact on the environment. More than ever, customers demand transparency in the sourcing, handling, and distribution of their food, directly impacting brand loyalty and trust. The traditional supply chain models, with their lack of real-time data, inadequate traceability, and absence of predictive capabilities, lead to inefficiencies and, consequentially, lost opportunities. Hence, there is an undeniable need for modern, technology-integrated supply chain practices.

Embracing Technological Transformation

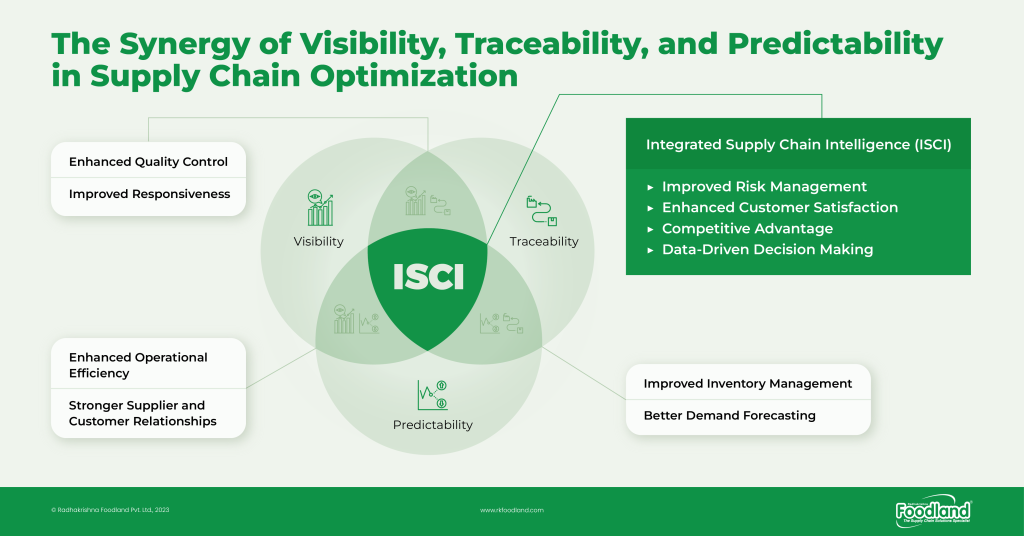

In an environment where decisions need to be made swiftly and accurately, on-demand data access is crucial. This close to real-time visibility allows businesses to make better decisions, enhancing operational efficiency and enabling faster response times to market changes. Traceability systems are at the forefront of this transformation. Far from being just a tool to comply with regulatory requirements, these systems play a pivotal role in building brand trust and loyalty. Predictive analytics stands as a cornerstone in this technological shift. By harnessing the power of data, businesses can forecast demand, manage inventory more efficiently, enhance quality control, reduce waste, and improve supplier performance, in some cases realising 20% increase in customer satisfaction and a 10% reduction in supply chain costs. These analytics go beyond mere numbers; they offer actionable insights that can shape everything from procurement strategies to customer engagement tactics.

Realizing the Future of Supply Chain Management Today

The adoption of advanced supply chain practices is a significant leap forward, not just in terms of operational necessity but as strategic tools for business growth and sustainability. These practices, which were once considered futuristic, are now within grasp and are reshaping the landscape of food supply chain. Companies that integrate these technologies are seeing tangible benefits, including efficiency gains, cost reductions, and, crucially, enhanced customer satisfaction.

Take for instance, the solutions provided by RK Foodland, which serve as prime examples of how technology can be effectively utilized in SCM:

- Visibility – Control & Command Centre: At the heart of modern SCM is visibility. RK Foodland’s Control & Command Centre exemplifies how real-time monitoring of the supply chain can bring about unprecedented control and responsiveness. This visibility is not just about tracking; it is about gaining insights that drive decision-making, reduce response times, and improve overall supply chain performance.

- Traceability – Warehouse Management System (WMS), Digital Supply Chain (UnitXPro): RK Foodland’s implementation of traceability processes incorporated in WMS and UnitXPro underscores the importance of tracking products throughout the supply chain. These systems ensure that every product’s journey is documented and accessible, enhancing safety, reliability, and compliance. In an era where consumers and regulators demand transparency, these systems are invaluable in building trust and ensuring accountability.

- Predictability – Demand Planning (DemandXPro): The ability to predict and plan for future demand is a game-changer. DemandXPro, as a tool for demand planning, enables businesses to anticipate market trends, adjust inventory levels accordingly, and avoid the pitfalls of overproduction or stock shortages. This level of predictability not only optimizes resources but also aligns production with market demand, leading to more efficient operations and reduced waste.

In conclusion, realizing the future of SCM today is about harnessing these advanced technologies to not only meet the current challenges of the food service and FMCG sectors but to also pave the way for sustainable growth and development. The integration of visibility, traceability, and predictability capabilities transforms supply chains from a traditional cost centre to a dynamic value driver, essential for businesses aiming to thrive in a competitive marketplace. Are you prepared to transform your supply chain and launch your business into a new era of success?

Discover RK Foodland’s solutions for visibility, traceability, and predictability to revolutionize your supply chain operations.

Related Content | Foodland’s Resources