[Avg. read time < 4 mins]

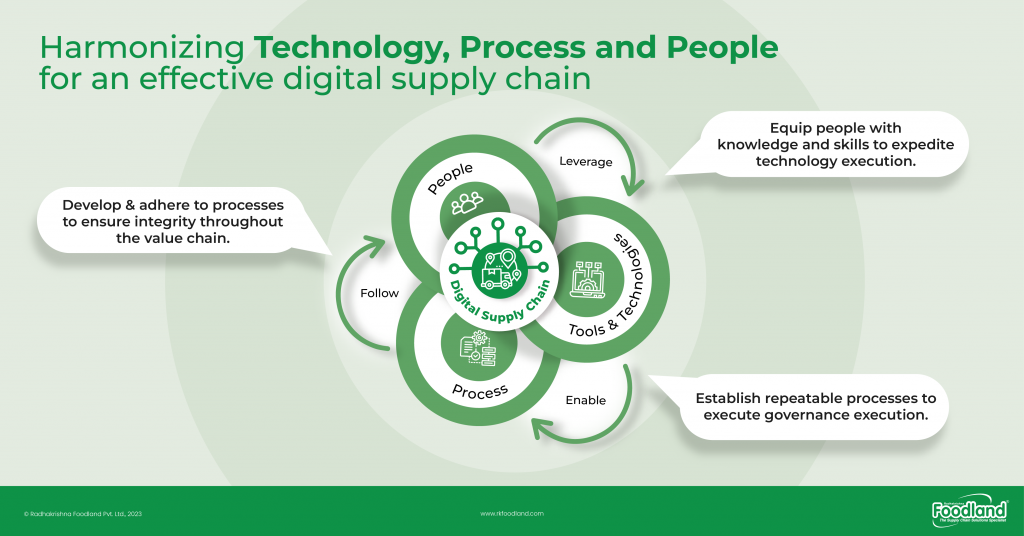

India, with its growing consumer base and changing market dynamics, offers both challenges and opportunities for the Food Service and Food FMCG sectors. For CXOs leading these industries, it’s evident that traditional supply chain models need an update. Embracing digital transformation is not just a strategic move—it’s essential for survival. As consumers increasingly seek transparency, traceability, and visibility, using advanced technologies becomes crucial to meet these needs and prepare for a future that’s efficient, resilient, and customer focused. However, this digital shift isn’t straightforward. A significant 83% of executives feel they are not harnessing the full potential of their supply chain technology investments, signifying there are critical missing links hindering optimal outcomes. We believe, achieving an effective digital supply chain requires – the fit-to-purpose technology, streamlined processes, and a skilled workforce. In this blog, we’ll explore these key elements, providing a guide for CXOs aiming to modernize their supply chain management.

Technology: Bridging Legacy to Digital

The food industry, with its rich history and time-tested practices, has always been anchored by traditional supply chain systems. These systems, built on decades of expertise, have reliably served the industry, propelling many leading brands to their esteemed positions today. However, as the world evolves, so do the demands and expectations of consumers and stakeholders. Transitioning from traditional to modern supply chains is not about replacing the old, but rather enhancing and augmenting it with the capabilities of today’s technology. In the context of the today’s technology ecosystem, modern systems such as cloud solutions, IoT devices, and Artificial Intelligence (AI) are emerging as powerful allies. A notable 61% of supply chain professionals view these as key drivers for a competitive advantage. These tools provide insights that monitor food quality, temperature, and other essential parameters, ensuring that products meet the highest standards. Moreover, with the increasing emphasis on food safety and compliance, systems that guarantee traceability are becoming indispensable. They foster trust and ensure adherence to safety standards. The beauty of this transition lies in the fusion of legacy systems with new technologies, allowing businesses to leverage the best of both worlds without disrupting their core operations.

Prerequisites:

- Integrated Platforms: Embracing platforms that can seamlessly integrate with traditional business systems is key. This provides end-to-end visibility allowing data access, bridging the gap between legacy practices and modern demands.

- Data Analytics and AI: The power of analytics and AI cannot be understated. They offer insights that can refine demand forecasting, inventory management, and identification of market trends.

- Traceability and Transparency: As the industry moves forward, ensuring end-to-end product traceability is paramount. It’s a testament to a brand’s commitment to safety and building trust with consumers.

Processes: Streamlining for Efficiency and Accuracy in the Digital Era

Having established a technological base by transitioning from traditional to digital platforms, the subsequent crucial move is to fine-tune the procedures overseeing the digital supply chain. In our current digital era, the term “operational chaos” has evolved. Disorganized digital operations can amplify inefficiencies, leading to heightened errors and escalating costs. Moreover, in a consumer landscape where real-time updates and prompt deliveries are the norm, any digital operational misstep can quickly diminish customer satisfaction and damage a brand’s online reputation.

The shift from this digital disarray to a well-coordinated digital operation is not just a change—it’s a transformation. Embedding digital transformation within the supply chain can potentially elevate revenues by 20% and drastically cut down process expenses. These organized digital processes, bolstered by cutting-edge technologies, set the stage for informed decision-making, optimal resource distribution, and improved profit margins. The goal is to foster a cohesive digital workflow where every department and function is interlinked, exchanging real-time data and insights. The ripple effect of such refined digital processes is immense, ensuring not just immediate operational efficiency but also long-term growth, adaptability, and a distinct advantage in an ever-evolving digital market. And, as is the nature of the digital world, this enhancement journey is cyclical, demanding a steadfast dedication to leveraging emerging technologies and insights to perpetually refine the digital supply chain.

Prerequisites:

- Standardization: In the digital landscape, consistency is key. Implementing standardized processes across the digital supply chain minimizes errors and sets the stage for scalable growth.

- Continuous Improvement: The digital world is ever evolving. To stay at the forefront, it’s imperative to continuously refine digital processes, leveraging data insights to ensure agility and adaptability to market shifts.

- Process Management: Streamlined processes lay the foundation for seamless integration and efficient operations. By consistently refining and optimizing workflows, organizations can ensure that best practices are not only identified but also implemented across the board. This proactive approach paves the way for a robust digital supply chain.

People: Driving Supply Chain Excellence

Building on the technological and process-oriented advancements we’ve delved into, there’s a pivotal element that many businesses inadvertently overlook: People. Recent findings indicate that while a staggering 93% of companies are actively engaged in digital transformation, a significant 53% identify a people/skills deficit as the primary obstacle hindering their progress. While technology and processes form the backbone of the digital supply chain, it is the human element that breathes life into it, driving change and actualizing visions. Recognizing the invaluable role of people is paramount. It’s not just about introducing new systems; it’s about harnessing the collective expertise that comes from blending the technical prowess of new-age experts with the rich, on-ground experience of long-standing employees. This synergy is where the magic happens, leading to innovative solutions and unparalleled efficiency. In this era of rapid digital transformation, continuous learning and growth stand as non-negotiables. Equipping teams with the latest knowledge and tools ensure that business remains agile and ahead of the curve. At the helm of this transformation should be leadership that deeply understands the industry’s intricacies, offering the organization both visionary insight and a distinct competitive advantage.

Prerequisites:

- Training and Upskilling: The digital era demands a workforce that’s not just skilled but continuously evolving. Regular training sessions and upskilling initiatives are essential to equip teams for the challenges and opportunities of digital transformation.

- Collaborative Culture: In the interconnected world of digital supply chain, silos are detrimental. Promoting cross-functional teamwork is key; by exchanging best practices and adopting proven strategies, we seamlessly tackle challenges together. Working in unison allows us to craft comprehensive solutions that leverage collective expertise and insights.

- Stakeholder Engagement: Stakeholder engagement serves as the cornerstone for success. Rather than merely being recipients of change, stakeholders become active contributors, shaping the direction and outcomes of digital initiatives. Their involvement guarantees that the digital supply chain is not just technologically advanced but also aligned with real-world needs and expectations.

The digital supply chain, while anchored by technology, processes, and people, requires a deeper layer of preparation. For CTOs, it’s not just about embracing the triad but ensuring the prerequisites are firmly in place. Standardized processes, continuous upskilling, and a culture of collaboration are the foundational elements that need meticulous attention. Without these, even the most advanced digital strategies can falter. As you stand on the cusp of this transformative journey, it’s imperative to ensure that every piece of the puzzle fits perfectly. Our experts have championed this holistic approach for numerous partners, ensuring that their transition to a digital supply chain is both smooth and successful.

Engage with us, and together, let’s chart a course to digital supply chain mastery.

Related Content | Foodland’s Resources

- How much is technology transforming supply chains?

- Digital supply chains: increasingly critical for competitive edge

- Supply Chain Digital Transformation: Why It Should Matter to Your Organization?