[Avg. read time < 4 mins]

In a market driven by consumer demand, the essence of reaching out to customers efficiently lies at the heart of a well-structured supply chain network design. Unlike the one-size-fits-all models, this tailored approach ensures a smooth sail of products from their point of origin to the consumer touchpoints, eliminating hurdles and bottlenecks. The strategic essence of this planning approach unfolds the potential for geographical expansion, making products easily accessible across a wider expanse. Through this lens, the design of the supply chain network transcends a mere logistical setup, to become a strategic asset that amplifies customer reach and satisfaction. As we delve deeper in this blog, we will explore the criticality of optimizing the supply network, the foundational blocks of supply network design, and the lasting impact of strategic network planning on meeting the ever-evolving market demands.

Why Optimizing Supply Network is Crucial

In the bustling Food Service and Food FMCG sectors, the pulse of success resonates through a finely tuned supply chain network. The essence of this tuning lies in striking a harmonious balance between service excellence and cost-effectiveness, a melody that plays well in the ears of both the stakeholders and the customers. Picture a popular QSR chain, where the appeal lies in the freshness of its juicy burgers. The optimized supply network is the cornerstone, ensuring timely delivery of diverse ingredients from various sources to the outlets. Strategic warehouse locations and efficient routing minimize the journey from suppliers to the grill, sealing the freshness in every bite. In this bustling chain, the supply network is the unsung hero, making every burger served a testament to the brand’s promise of freshness and taste. The plot thickens when we add the layers of risk mitigation and assurance of supply to this narrative, especially when considering that 32% of companies are losing revenue due to supply shortages.

Now imagine a popular food FMCG brand’s demand suddenly spikes due to a festive season. Here the supply network’s design is put to test. An optimized network swiftly responds to this surge, ensuring shelves are restocked promptly, keeping the festive spirit high and uninterrupted. This is particularly significant as only 22% of companies were working with a proactive supply chain network in 2022, showcasing the competitive advantage of an optimized supply network.

In a market where competition is as diverse as the food palate, having a streamlined supply chain is like having a secret sauce. It not only adds a flavour of reliability and trust in the brand but also garnishes it with a competitive edge. Moreover, with driver wages and fuel costs alone making up 59.8% of the total operational cost per mile, an optimized supply chain not only ensures reliability but also significantly impacts the bottom line. In a nutshell, optimizing the supply chain network is not a mere operational strategy; it is a crucial ingredient in the recipe of success for Food Service and Food FMCG businesses.

Building Blocks of Supply Network Design

Understanding customer needs is central to designing a supply chain network, as other elements of the supply chain revolve around these needs. The objective is to ensure that the supply network is structured in a way that it can respond adeptly to market demands while maintaining cost-effectiveness.

A pivotal aspect of this designing process is the utilization of data and analytics. By harnessing historical data and employing forecasting models, it becomes possible to forecast demand trends and plan accordingly. However, nearly 53% of companies cited poor data quality, and 30% pointed out a lack of skilled resources as the most common obstacles. This predictive approach facilitates a more responsive supply chain network that can adapt to demand fluctuations, ensuring timely deliveries and minimizing stockouts or overstock situations.

50% of forward-thinking companies are now harnessing the power of technology for designing their Supply Chain Network, with 37% relying on expert consultants for deployment. At the heart of this transformative design process lies robust specialized software tools like NetworkXPro. Such tools aid in strategic network planning by providing insights derived from data analytics to translate the abstract aspects of supply network design into actionable plans.

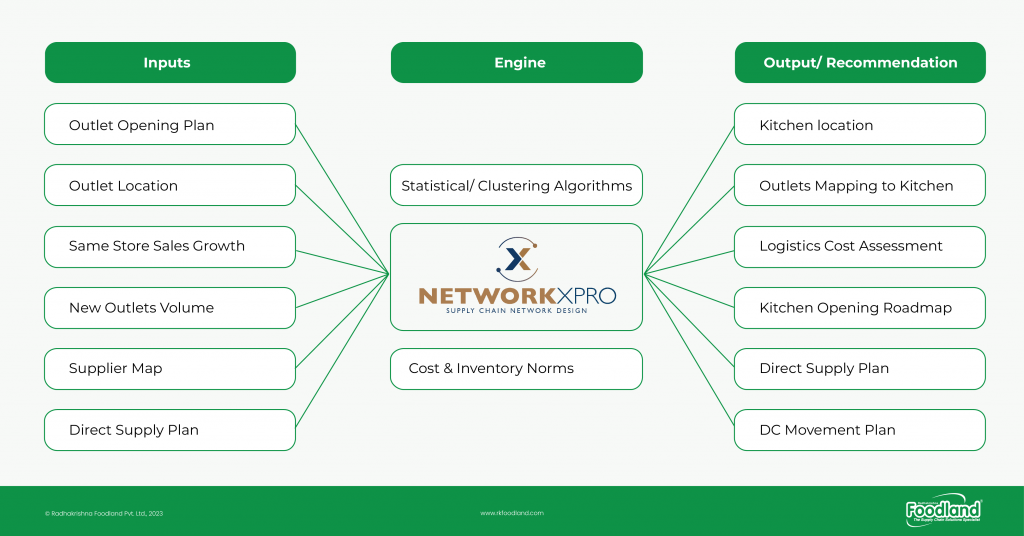

The process of network designing using NetworkXPro can be outlined into three primary segments: Inputs, Engine, and Outputs.

The building blocks of supply chain network designing are a blend of customer-centric planning, data-driven decision-making, and technical application. Each block is meticulously crafted and assembled, ensuring that the resultant supply chain network is robust, responsive, and aligned with both business objectives and customer expectations.

Impact of Strategic Network Planning

Strategic network planning is essentially about making smart, informed decisions to ensure that the supply chain operates smoothly and efficiently. For supply chain professionals and food businesses, this planning is a roadmap to achieving better operational efficiency and performance delivery through:

- Prioritizing reach ensuring product availability and accessibility anytime, anywhere.

- Thoughtful location of distribution centres and outlets shortening product journey from production to customer, enhancing efficiency.

- Streamlined routes and optimized vehicle utilization cutting down logistics costs and improving delivery times, crucial for maintaining product integrity.

- Strategic planning for new restaurant or store opening aids in accurate location and capacity decisions.

- Financial benefits including controlled expenses and better inventory management, leading to lower working capital requirements.

- Optimized network design curtailing fixed costs (facilities, equipment) and variable costs (labour, handling), aiding budget management and resource allocation.

- Provides clear visibility across the supply chain network on processes and costs, enabling informed decision-making.

- Less guesswork, more data-driven decisions for SCM professionals, making their roles less stressful and more productive.

Supply chain network planning & designing is about simplifying the complex, making the day-to-day supply chain operations of food businesses and the SCM professionals easier and more effective.

In conclusion, strategic planning and design of a supply chain network are crucial for meeting consumer demands efficiently, especially in the Food Service and Food FMCG sectors. It is more than an operational strategy; it is a competitive advantage that ensures timely delivery of products, cost-effectiveness, and customer satisfaction. Tools like NetworkXPro are key in making this planning process data-driven and actionable.

Reach out to our experts to learn more about Network Designing and get a demo on NetworkXPro to unveil the potential of optimized supply chain networks in propelling your business to new heights of operational efficiency and market responsiveness.

Related Content | Foodland’s Resources

Supply Chain Network Design: Importance, Benefits, Types & Contributing Factors

How location intelligence is changing delivery route optimization for food tech brands

Why is it Crucial for F&B Brands to Design an Ideal Supply Chain Network?