[Avg. read time = 4 mins]

Imagine a world where every business seamlessly adapts to market changes and effortlessly expands into new territories. Now, confront this idea with the harsh reality of fragmented supply chains, a prevalent issue undermining the very foundation of such aspirations.

Consider the case of a QSR chain, ambitious to capture new markets. Despite its innovative menu and aggressive marketing, the chain struggles to maintain consistency and speed across its outlets.

Why? The culprit is a supply chain, broken into disjointed segments, each operating in its silo. A single ingredient’s shortage or a delayed shipment snowballs into a widespread operational fiasco, tarnishing the brand’s reputation and customer trust.

In this blog, we will dissect the multifaceted impact of fragmented supply chains, not just on day-to-day operations but also on long-term strategic goals. It’s startling to note that according to the Supply Chain Resilience Report, fragmented supply chains can reduce a company’s efficiency by up to 30%. This statistic underpins the gravity of the issue at hand.

Our exploration will reveal how this fragmentation, far from being a mere operational hiccup, poses a significant barrier to scalability and market responsiveness, ultimately stifling growth and eroding profitability in the long haul.

Strategic Aspects of Fragmented Supply Chains

Fragmented supply chains often result in a crucial disconnect between the supply side and the demand side. This misalignment is rooted in the lack of effective communication and collaborative planning. In disjointed supply chains, goals and operations across various segments fail to align, leading to conflicting objectives and inefficiencies.

Imagine a specialty coffee chain striving to align its bean supply with fluctuating demand forecasts. This scenario highlights the first strategic challenge: effective planning and forecasting are nearly impossible when the supply chain is a jigsaw puzzle of mismatched pieces. The result? Either a surplus of beans leading to waste or a shortage causing lost sales.

A survey found that 67% of respondents have implemented digital dashboards for end-to-end supply chain visibility, indicating a strong correlation between integrated supply chain approach, visibility and the ability to avoid supply chain problems. This suggests that companies with better visibility are twice as likely to avoid disruptions

Furthermore, limited information sharing and collaboration significantly impede innovation and development. Such fragmentation stifles the capacity for strategic decision-making and responsiveness to market changes, ultimately hampering business growth. When supply chain segments operate in isolation, they cannot effectively adapt to or predict market demands, leading to missed opportunities and wasted resources.

Consider the case of a frozen food company struggling to source healthier ingredients. Its scattered supply chain thwarts its ability to adapt to the rising demand for nutritious options. Consequently, the company witnesses a decline in its market share, outpaced by nimble competitors.

Expansion into new markets also presents a formidable challenge. Take a pizza franchise attempting to establish itself in a new country. Its success is compromised by varying product quality and service due to inconsistent supply chain practices across borders.

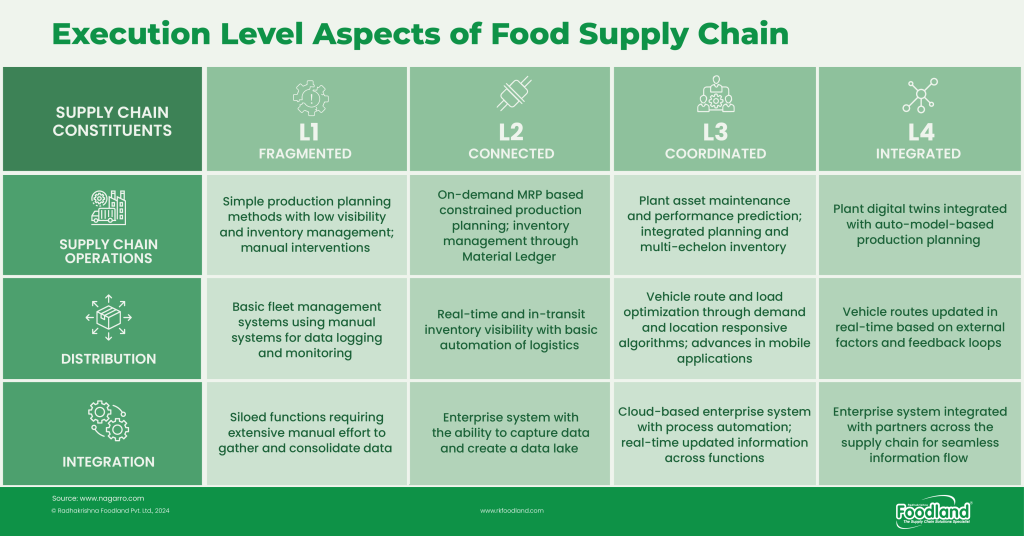

Execution Level Aspects of Fragmented Supply Chains

On an executional level, fragmented supply chains lead to a duplication of efforts and resources. This redundancy is not just inefficient but also adds unnecessary complexity to resource allocation.

Consider a seafood restaurant chain grappling with high costs from sourcing fish through multiple, uncoordinated suppliers. These redundancies eat into profit margins, a classic symptom of tactical inefficiencies in a fragmented supply chain.

Managing a segmented supply chain requires more effort, increased coordination, and often results in a misallocation of valuable resources. These inefficiencies directly impact growth by increasing operational costs and reducing the overall effectiveness of the supply chain.

Moreover, fragmented supply chains struggle with maintaining consistent quality control measures. The lack of a unified approach leads to delayed identification and response to quality issues, directly impacting product integrity and customer satisfaction which are critical for long-term business growth.

The inability to quickly identify and address these issues due to a fragmented supply chain structure further exacerbates the problem, leading to a cycle of inefficiency and decreased customer satisfaction.

Long-term Growth and Profitability

In the long-term, the inefficiencies and missed opportunities inherent in fragmented supply chains translate into increased costs. These costs are not just financial; they encompass the lost potential for growth and market reach. Businesses face significant challenges when entering new markets or launching new products, as the lack of cohesion and coordination in their supply chains leads to delays and inefficiencies, hindering their ability to compete effectively.

Managing and implementing sustainable practices is another area where fragmentation takes its toll. When supply chain segments operate independently, ensuring uniform adherence to sustainability standards becomes a complex task. This inconsistency can damage a brand’s reputation and its commitment to corporate responsibility.

Moreover, fragmented supply chains expose businesses to heightened risks, including supply disruptions and market volatility. These risks are magnified when there is no unified strategy to manage them, making the business more vulnerable to external shocks.

Central to these issues is the difficulty in striking a balance between service, quality, and assurance in fragmented supply chains. Each segment might prioritize differently, leading to a misalignment that impacts the overall value proposition of the business. This imbalance can result in compromised service delivery, inconsistent product quality, and a general inability to assure stakeholders of steady, reliable performance. As a result, the long-term growth and profitability of businesses are significantly hampered, leaving them struggling to maintain competitiveness and market relevance.

Think fragmented supply chains are just a minor setback? Discover how much more your business can achieve with an integrated approach. Connect with our experts to discover how an integrated supply chain can not only streamline your operations but also accelerate your business growth.

Unlock the full potential of your business with an integrated supply chain.

Reference Links:

Related Content | Foodland’s Resources

Supply Chain Fragmentation Explained

The Supply Chain Is Complex, Fragmented, and Under Pressure: How Best To Handle?

Moving from fragmented to coordinated management

How To Manage A Fragmented Supply Chain